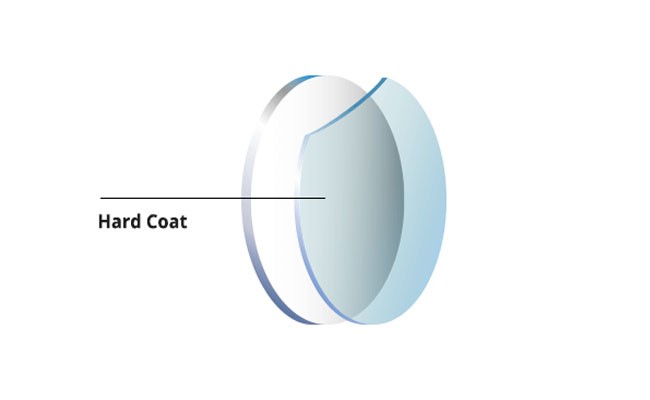

Hard coat are today a standard within an anti reflection coating lenses.Therefore lacquers are used which form an almost perfect buffer among the lenses surface and the extra brittle AR coating.

A high quality thermally cured hard coat gives the great scratch resistance and gives for the maximum long lasting component for an AR coating application. Plastic lens substances scratch without problems than glass substances, and therefore gain greatly with application of a durable hardcoat.

Both Side dip automated coated lenses for longer existence. Coating thickness is exactly controlled with the aid of absolutely automized machine as a consequence giving lens highest quality scratch resistant assets.

Two of the extra common Varieties of hard coats are: Thermally cured hard coating The lens is slowly surpassed through a liquid bathtub of a solvent based hardcoat where the coating solution adheres to each convex and concave facets of the lens. The hardcoat is then allowed to therapy in an excessive temperature oven till solid. U.V. Cured hard coating A liquid hardcoat solution is implemented to the concave side (backside) of the lens, the use of a spinning process. Lenses are then cured under a UV (Ultra Violet) light for a particular period of time.